Sheet Metal Flange

Status: Implemented

Sheet Metal Flange bends one or more thin side faces away from an existing sheet metal body. It reuses the base face and hinge edge to revolve a bend, offsets it to match typical inside/outside measurements, and can optionally extend a straight leg past the bend.

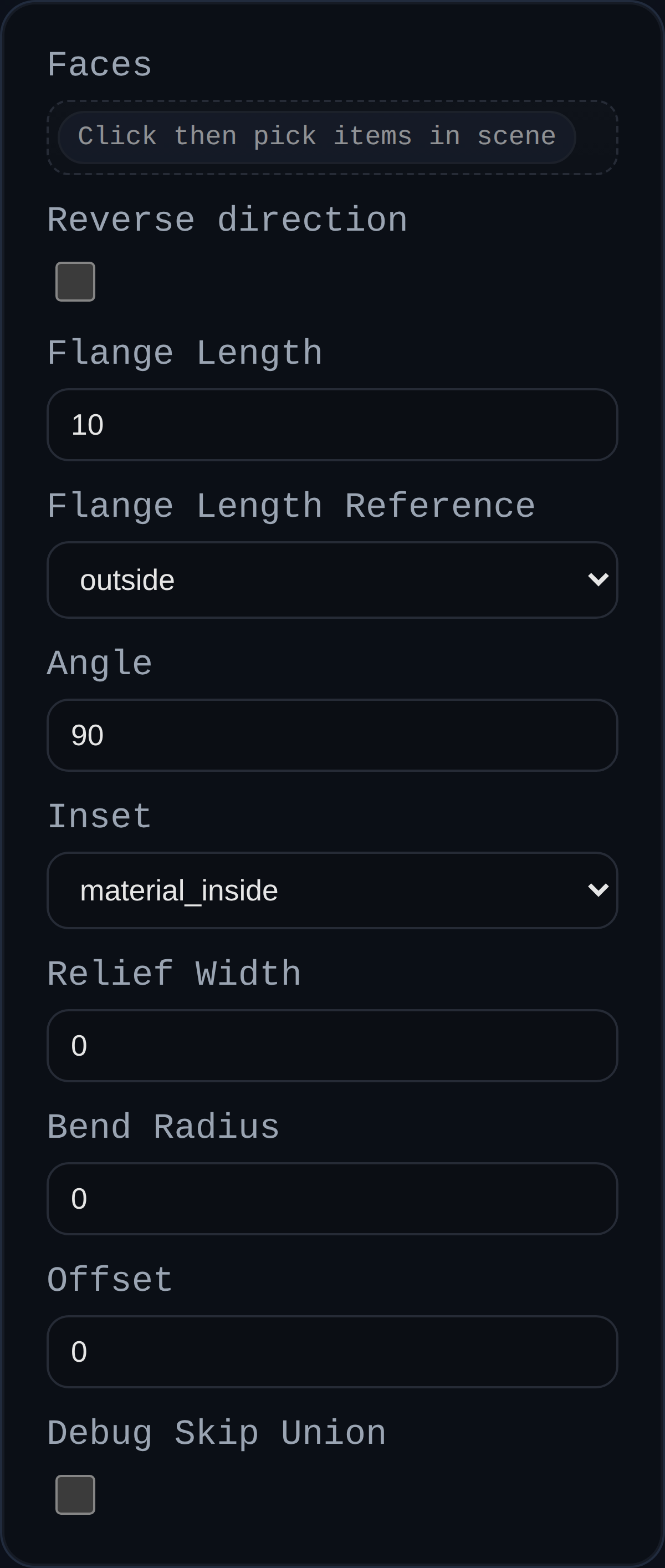

Inputs

faces– Thin side faces that define the bend profile. The feature reads sheet-metal metadata on these faces/solids to recover thickness and default bend radius.angle– Bend angle relative to the parent sheet (clamped 0–180°; 90° is perpendicular).useOppositeCenterline– Reverse which sheet-metal edge (A vs B) is used for the hinge if the default folds the wrong way.flangeLength– Optional straight leg length extruded from the bend end face. Set to0to create only the bend.flangeLengthReference– Measurement basis for the straight leg:inside,outside, orweb(no adjustment). Inside/outside references subtract bend radius and/or thickness to align with common flange callouts.inset– Positions the bend centerline relative to the source face:material_inside,material_outside(default), orbend_outside. Each preset offsets by the bend radius/thickness before building the bend.offset– Additional manual inset/outset distance applied along the face normal. Negative values cut a matching pocket from the parent sheet; positive values shift the bend outward.bendRadius– Optional override for the bend radius. Defaults to the parent sheet’s stored radius or the inferred thickness when metadata is missing.reliefWidth– Extra clearance added to negative offsets when trimming into the parent sheet to avoid coplanar artifacts.debugSkipUnion– Return raw bend/offset solids without uniting them back into the parent (for debugging).

Behaviour

- Derives sheet thickness and default bend radius from the selected face/solid metadata (

sheetMetalThickness/sheetMetalBendRadius), falling back to thickness1when absent. - For each face, picks a hinge line (favoring faces tagged

A/B) and revolves the face by the requested angle. A second pass retunes the hinge offset if the measured bend radius drifts from the target. - Applies inset/outset and manual offsets before creating the bend; negative offsets subtract a spacer from the parent sheet when possible, while positive offsets translate the flange outward.

- When

flangeLengthis non-zero, extrudes a flat leg from the bend end cap, honoring the selected length reference and any offset translation. - Attempts to union every generated flange back into its parent solid, but falls back to returning separate solids if the boolean fails or union is disabled.

- Tags outputs with

userData.sheetMetal(baseType: FLANGE, thickness, bend radius, angle, inset mode, offsets, etc.) and mirrors the values into theMetadataManagerfor downstream sheet-metal operations.